Industrial pumps are an integral part of many industries, from mining to manufacturing. Without them, industrial processes couldn’t be completed efficiently or cost-effectively. But what exactly is an industrial pump, why are they essential for industry, and how do you know which one is best for your business? In this blog post, we will dive into the world of industrial pumps so you can gain a better understanding of their importance and learn why investing in the right type could benefit your enterprise over time.

Overview of Industrial Pumps and Their Applications

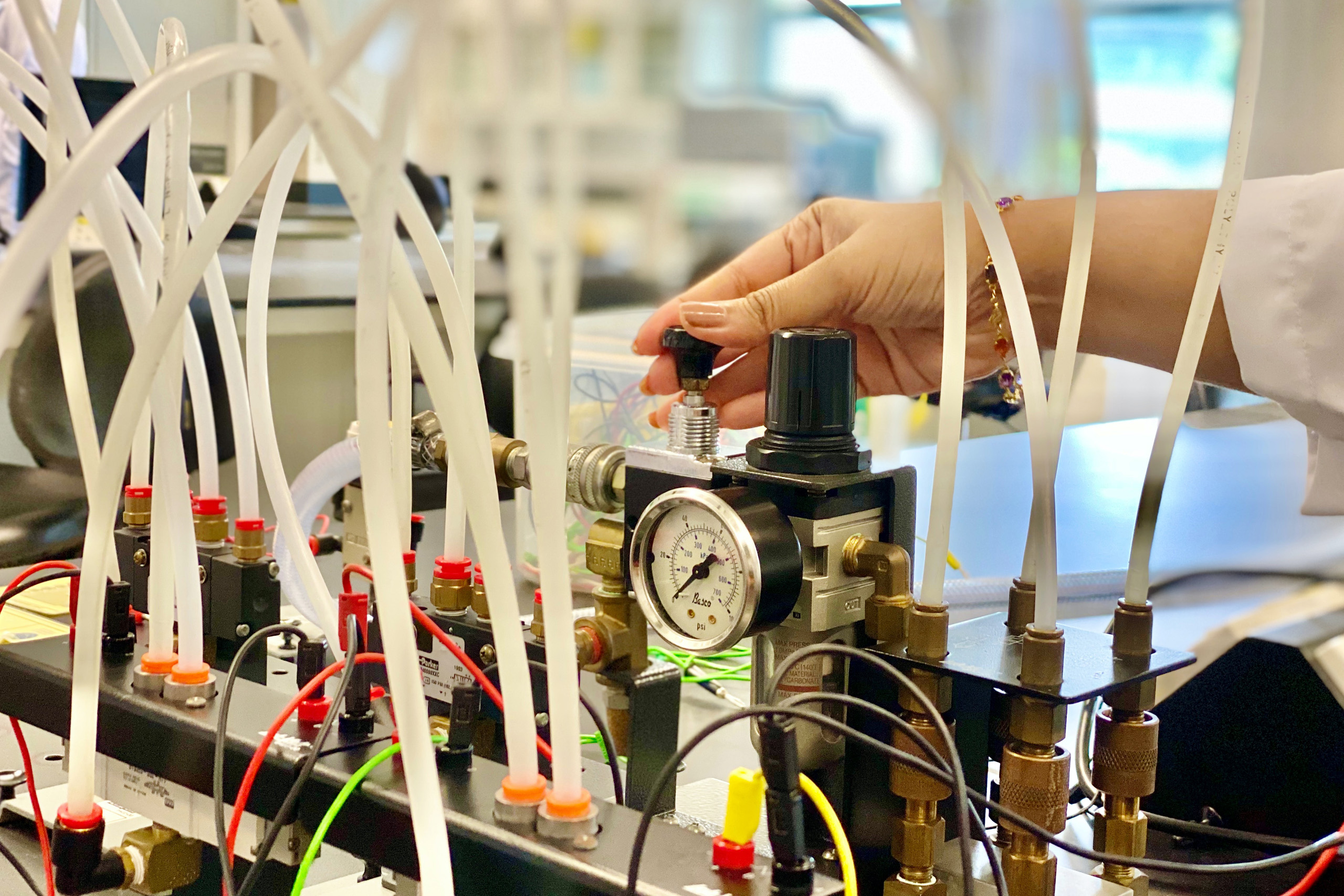

Industrial pumps are essential equipment that plays a crucial role in modern manufacturing processes. These pumps are designed to move fluids, such as chemicals, water, oil, and gas, from one location to another. The types of pumps used will vary depending on the type of application required. For instance, centrifugal pumps are ideal for low-viscosity liquids such as water, while positive displacement pumps are better suited for high-viscosity fluids such as oil. The wide range of industrial pumps available makes it possible to tailor them to a specific task. Whether you're moving materials from one location to another, or simply need to keep fluids circulating in a system, choosing the right pump can help increase efficiency and productivity.

Benefits of Using Pumps in Industrial Settings

In industrial settings, pumps are an essential component for a variety of tasks, from moving fluids to maintaining pressure levels. The benefits of using pumps are numerous and significant, including increased efficiency, reduced downtime, and lower maintenance costs. Pumps allow for the transfer of fluids over long distances and elevations while ensuring that the fluids remain at a consistent pressure. This means that processes can run smoothly without any interruptions or delays, resulting in higher productivity and profits. Additionally, pumps can handle a wide range of fluids, including those that are corrosive or contain solids, making them a versatile option for various industries. With their ability to improve performance and reliability, it's clear that pumps are an invaluable asset to any industrial setting.

Different Types of Pumps are Available

When it comes to pumping systems, there are several types of pumps available to choose from. Understanding the various types of pumps will enable you to select the one best suited for your application. Centrifugal pumps are the most commonly used type, converting rotational energy into fluid motion to move water or other liquids. Positive displacement pumps, on the other hand, trap fluid in a chamber and force it through a discharge pipe using mechanical or hydraulic action. They are ideal for applications requiring high pressure and low flow rates. Submersible pumps are also popular, particularly in groundwater control and sewage management systems. They operate underwater and are able to withstand high water pressure. Ultimately, selecting the right pump, whether it's an acid pump or diaphragm pump, for your needs will depend on a variety of factors, including the type of fluid being handled, the flow rate required, and the operating pressure necessary for your particular application.

Advantages and Disadvantages of Different Pump Models

When it comes to choosing a pump model, there are a variety of options available, each with its own set of advantages and disadvantages. Centrifugal pumps, for example, are great for high flow rates but struggle with high-viscosity liquids. Positive displacement pumps, on the other hand, can handle high-viscosity fluids with ease. However, they are limited in terms of how much flow they can generate. Being aware of these pros and cons will help you make an informed decision about which pump model will best suit your specific needs. Additionally, always ensure that you seek advice from a certified professional before making any final decisions.

Tips for Choosing the Right Pump for Your Particular Needs

Choosing the right pump can be a daunting task, but it doesn't have to be. First, consider the type of liquid or gas you'll be pumping. Different fluids have different viscosity levels, which affect the flow rate and pressure required from the pump. Next, determine the required flow rate and pressure for your application. This will help you determine the pump size and model needed. Don't forget to consider the size and compatibility of the inlet and outlet ports. And lastly, consider the operating conditions and any special requirements, such as material compatibility, hazardous area ratings or budget constraints. With these tips in mind, you'll be able to choose the right pump for your particular needs with confidence.

The Importance of Regular Maintenance on Your Industrial Pumps

Industrial pumps play a critical role in the smooth functioning of various industries. However, like any other machine, pumps can develop problems if not properly maintained. Regular maintenance is crucial to ensure your pumps perform at their best and avoid costly downtime. Ignoring signs of wear and tear can lead to a decrease in efficiency and even complete pump failure. By scheduling regular check-ups and maintenance, you can detect problems early and address them before they turn into major issues. So, be proactive in maintaining your industrial pumps and save yourself from unexpected downtime and repair costs.

In conclusion, industrial pumps can be an invaluable asset to help create an efficient and productive industrial environment. Although there are many different styles of pumps available on the market for various applications, comparing their advantages and disadvantages is essential for choosing the right pump for your specific requirements. Whilst it might seem straightforward, it pays to do your research beforehand in order to select the most suitable product. Furthermore, it is important not to neglect regular maintenance in order to ensure optimal performance and longevity of your industrial pumps so that you can reap all the benefits that they have to offer. By staying informed and utilizing the above tips, you will surely make a smart investment in a quality industrial pump that will pay off in the long run.